ptfe coatings

Polytetrafluoroethylene DRy release COATINGS by rothgreaves

Quick Guide: See full table here

DR-95Z Grey: For complex profiles, contours, and ID coatings

DR-96 Green: Ideal for applications needing a green finish

DR-97 Lt Grey: Similar to DR95Z, but more durable for parts

DR-472 Blue: Blue finish variant with durability like DR97

DR-100 Black: Suitable for applications needing a black finish

DR-00 Clear: Transparent finish, max length of 24 inches

Polytetrafluoroethylene (PTFE) is a fluorpolymer designed for use in applications that require high temperature stability and durability in a non-stick finish, used as a release agent in thermal bonding and injection molding, reflow, and adhesive bonding processes.

RothGreaves Dry Release (DR) PTFE formulations are so smooth you’ll feel the difference. These lubricious dry release finishes can be applied to nearly any tooling that requires a high working temperature, and high release properties.

The cured finish is biocompatible and has passed USP Plastic Class VI testing and can withstand temperatures up to 600 Fahrenheit making it ideal for use in the manufacturing of medical devices and food contact products.

The superior durability and smooth finish places them amongst the best and most reliable release finishes available on the market today.

Medical and Food Grade PTFE Coatings FAQs

RothGreaves DR PTFE cured finish is biocompatible and has passed USP Plastic Class VI testing making it suitable for use in the manufacturing of medical devices and food contact products.

See Safety Data Sheets (SDS) below:

Do you have medical grade coatings?

Our coatings are medical grade and biocompatible according

to USP Plastics Class VI Certification.

Do you offer any coatings other than PTFE?

Our focus is providing PTFE coating services.

What color PTFE’s do you have?

Light grey, dark grey, blue, green, black, and clear.

What is your coating thickness?

Average .0003".

Will your coatings cover up scratches or blemishes?

Our coatings are capable of conforming to complex surface profiles and will cover minor blemishes.

What methods of sterilization can be used on medical parts?

Ethylene Oxide (ETO)

NOTE: These coatings are NOT recommended for use in implantable medical devices.

Which DR Coating Do You Need?

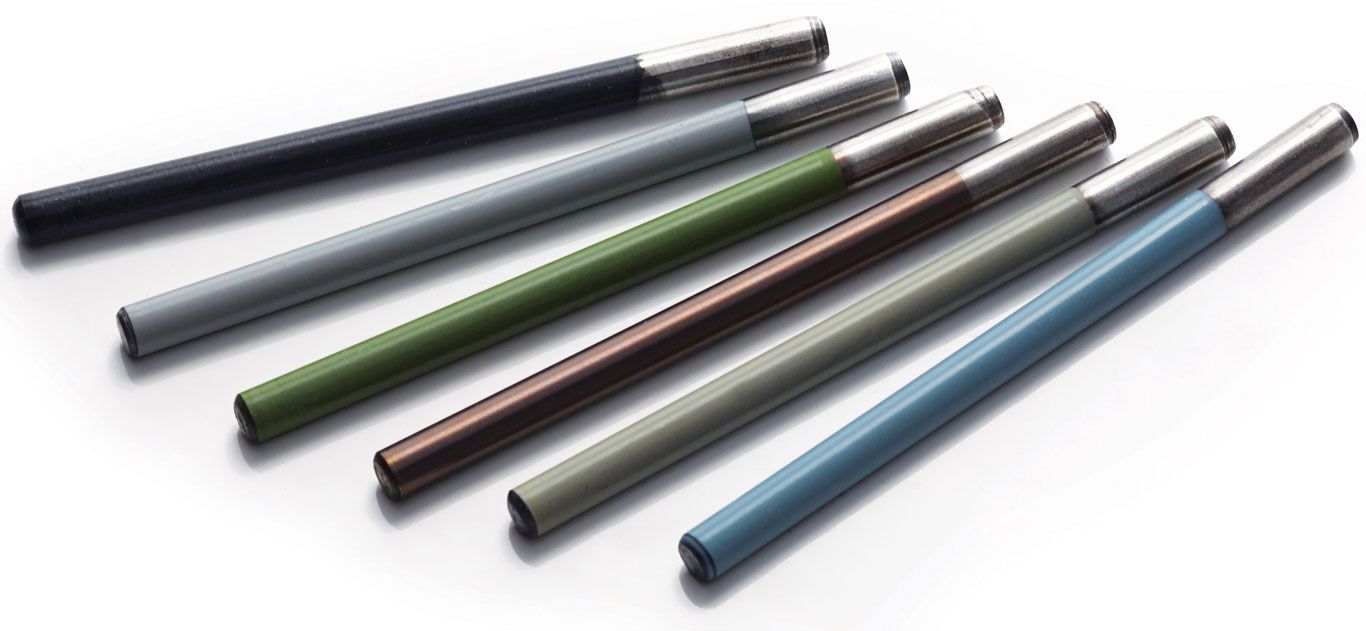

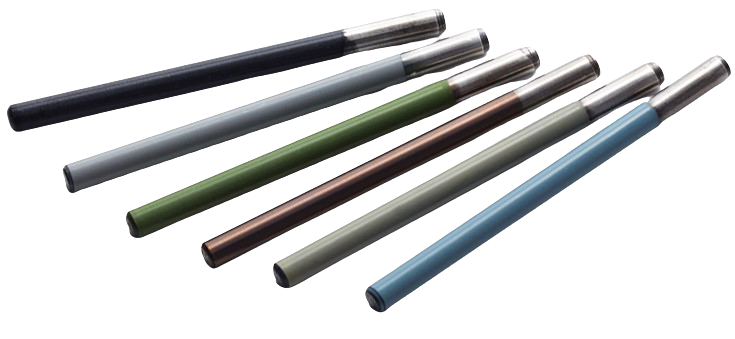

RothGreaves offers a range of proprietary DR PTFE finishes, including DR-95Z, DR-96, DR-97, DR-472, DR-100, and DR-00. Each formulation provides exceptional release properties and comes in different colors for quick and easy part identification.

Our superior release finishes are ideal for tooling used in medical device manufacturing, such as mandrels, hypotubes, core pins, and tipping dies.

PTFE Coating

Avg. Thickness

Coating Description

DR-95Z Grey

.0003" / Side

DR95Z has increased flowability and is recommended for parts with complicated profiles, challenging contours, sharp edges, as well as for interior ID coatings

DR-96 Green

.0003" / Side

DR96 is a color variant recommended in applications where a green finish is desirable

DR-97 Lt Grey

.0003" / Side

DR97 is a variation with similar properties to DR95Z but may provide increased durability on straight or slightly tapered parts

DR-472 Blue

.0003" / Side

DR472 is a color variant offered for applications where a blue finish is desirable and which may see increased durability similar to DR97

DR-100 Black

.0003" / Side

DR100 is a color variant offered for applications where a black finish is desirable

DR-00 Clear

.0001" / Side

DR00 is a coating without any color pigmentation, giving the material a neutral, transparent finish. Maximum length of 24"

* Please note that all RothGreaves DR PTFE formulas cure at 750 degrees Fahrenheit

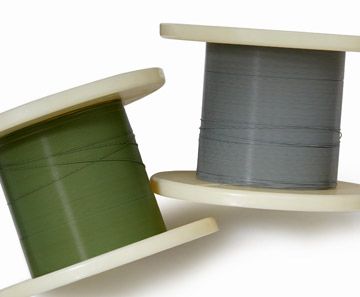

Orders for RothGreaves DR PTFE Coatings require no minimum or maximum quantity for standard parts with a coating length of 72″ or less, and minimum of 200 ft for reel-to-reel coating. Lead times are competitive, most orders shipping in 1–2 weeks.

Call 1-952-404-2604 or click the link below to get a price quote and estimated delivery times.

GLOSSARY OF DR PTFE COATING TERMS

DR PTFE Coating Processing Capabilities & Tolerances FAQs

What tolerances can you hold on medical devices and wires?

In most applications, coating will add .0001" to each side of the uncoated tolerance of the mandrel.

How do you measure coating thickness?

Our standard method is with a laser micrometer.

What is the longest medical device wire you can coat?

The longest discrete length is 72". We also provide continuous spool-to-spool coating services.

Can you mask sections of medical device wires?

Yes.

Can you coat nitinol?

Yes.

Can you coat medical device springs?

Yes.

Can you strip off old coating and re-apply new?

Yes

What is normal surface preparation?

We offer several surface preparation options to ensure parts are clean and ready to coat properly. Oily or dirty parts will not coat well.

What are the operating temperatures of your coatings?

Less than 600 F for short runs and less than 500 F for extended runs.

Do you have a Quality Control department?

Yes.

Can you certify your coating under a certain military spec?

We provide a Certificate of Compliance for every order based on customer supplied specifications. This may or may not suffice.

Are you ISO approved?

No, we are not ISO certified although our quality practices allow us to supply coating services to a range of industries.