RothGreaves’ EasyWind software makes it simple to develop the coil profile, teach to any operator, and be the most adaptable machine to any company’s production line. We offer an operator’s dream machine; the 5000 Automatic Winder can run unattended and still produce precise high-volume products. The 4000 series Manual Winders take advantage of the human operator to handle the most delicate coils. And our custom EasyWind software has the ability to teach any operator and is adaptable to most production lines with easy to use coil profile development.

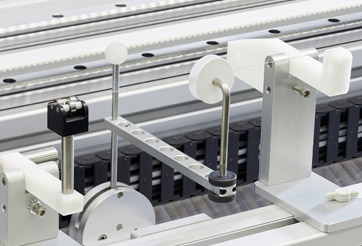

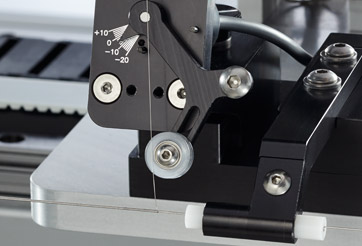

RothGreaves has developed the angle control compensator to eliminate the need for vision control, instead of allowing high speed operation. Our compensator is the most advanced form of pitch control on the market today. When this is combined with our active payout system, our coil winders produce the most precise coils.

RothGreaves has developed our proprietary EasyWind software; this custom software was created for multi-pitch, multi-segment, multi-speed coil profiling. This is the most advanced software on the market today. EasyWind advanced features have recipe development and full security level control. All of our machines are operated by a CNC servo controller for extreme accuracy and reliability.

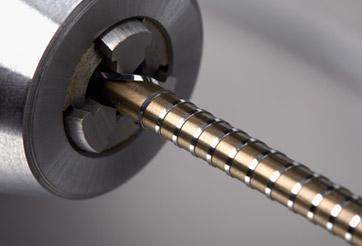

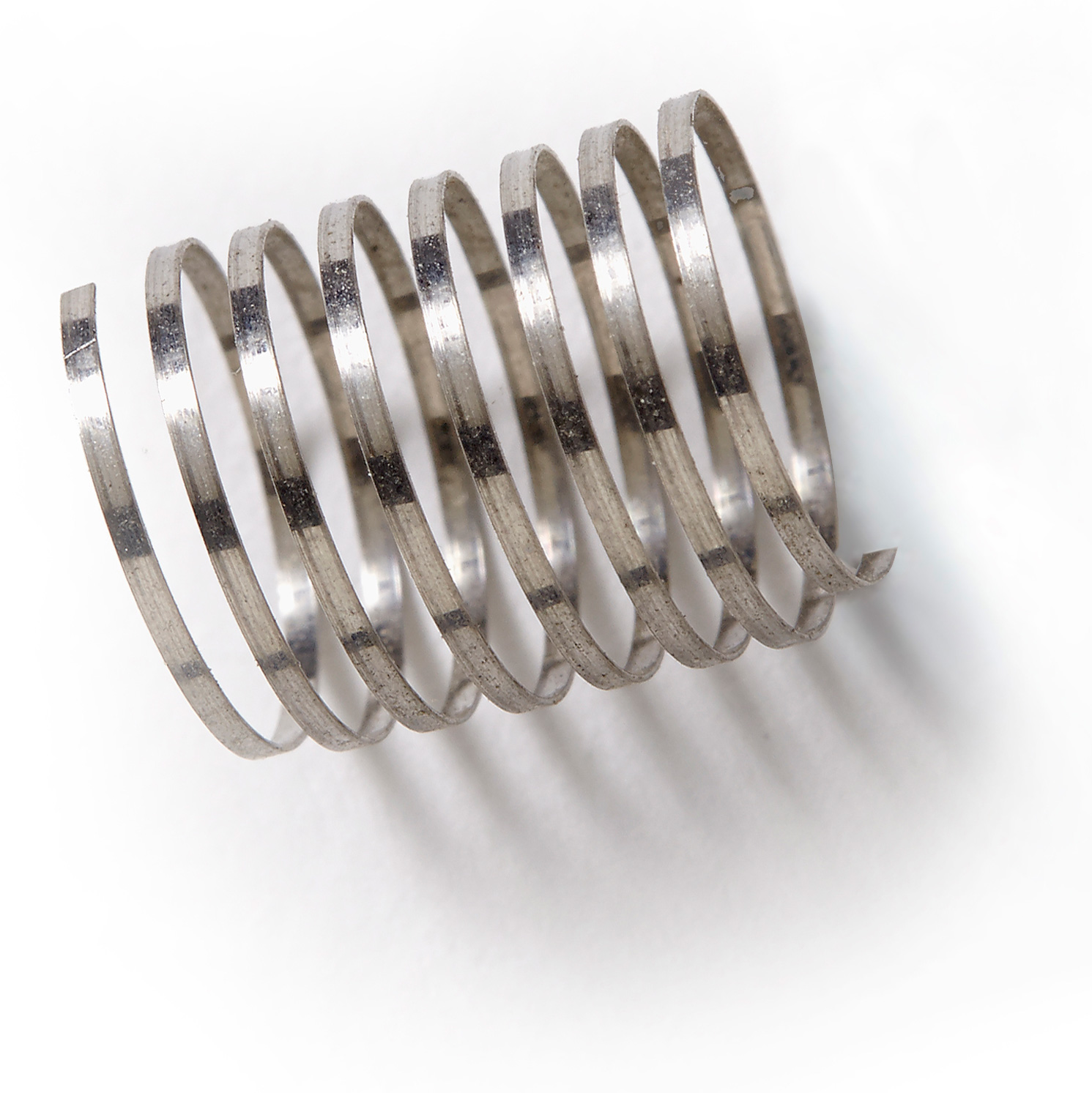

RothGreaves is the world’s leading manufacturer of micro-coiling winders with over 30 years in the coil winding business. Our engineers have extensive background in catheter and guide wire development.Some of our machines’ key features are high-rpm motors, electronic spool tensioners, analog pitch compensators, our famous EasyWind Windows™–based software with a full CNC coil winding control, and available with a multi-filar payout rack. We continue to lead the industry with innovative advancements developing high performance winders year after year.

RothGreaves is the world’s leading manufacturer of micro-coiling winders with over 30 years in the coil winding business. Our engineers have extensive background in catheter and guide wire development.Some of our machines’ key features are high-rpm motors, electronic spool tensioners, analog pitch compensators, our famous EasyWind Windows™–based software with a full CNC coil winding control, and available with a multi-filar payout rack. We continue to lead the industry with innovative advancements developing high performance winders year after year.